Porcelain Countertops

Exclusively made in Italy, Infinity’s state-of-the-art digital imaging technology results in true-to-life natural colorations within a surface that is virtually maintenance-free.

Infinity designs and produces large-sized slabs for countertops, fireplaces, furnishings and application on interior walls or for cladding of glued or ventilated walls.

Atlantis Grey

Infinity Porcelain Countertop

Calacatta Magnifico

Infinity Porcelain Countertop

Classic Statuario

Infinity Porcelain Countertop

Invisible Blue

Infinity Porcelain Countertop

Metal Silver

Infinity Porcelain Countertop

Orobico Luxe

Infinity Porcelain Countertop

Pietra Grey

Infinity Porcelain Countertop

Royal Peacock

Infinity Porcelain Countertop

Total Black

Infinity Porcelain Countertop

Calacatta Hermitage

Infinity Porcelain Countertop

Calacatta Oro

Infinity Porcelain Countertop

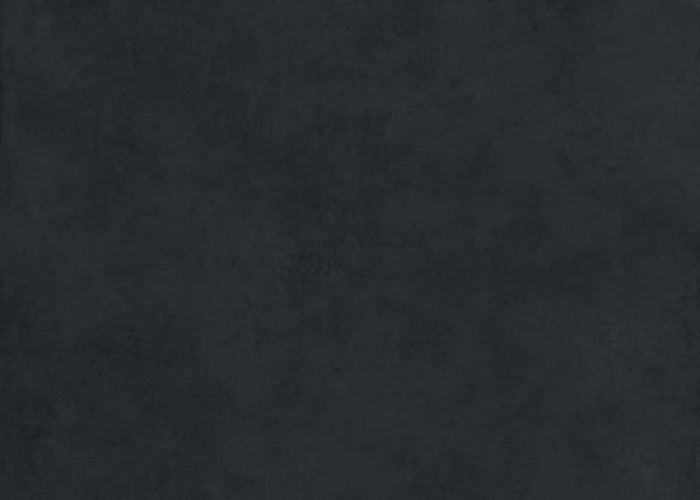

Concrete Grey

Infinity Porcelain Countertop

Magellano

Infinity Porcelain Countertop

Milan Stone

Infinity Porcelain Countertop

Panda White

Infinity Porcelain Countertop

Pulpis Brown

Infinity Porcelain Countertop

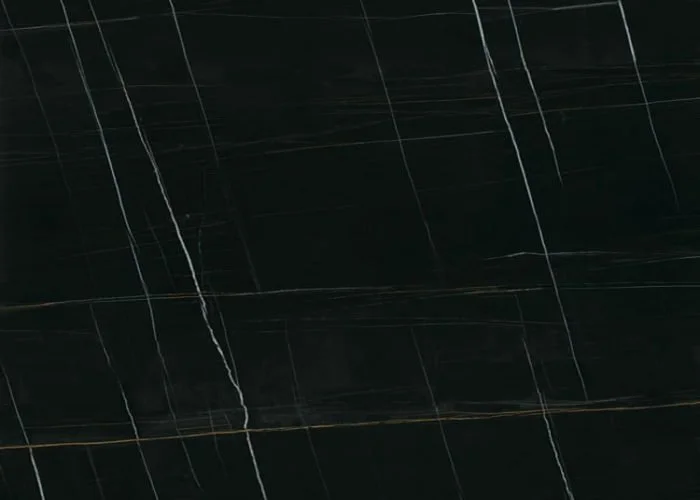

Sahara Noir

Infinity Porcelain Countertop

Calacatta Lincoln

Infinity Porcelain Countertop

Chianca di Ostuni

Infinity Porcelain Countertop

Extra Statuario

Infinity Porcelain Countertop

Metal Dark

Infinity Porcelain Countertop

Nero Marquina

Infinity Porcelain Countertop

Pierre Blue

Infinity Porcelain Countertop

Renoir

Infinity Porcelain Countertop

Terrazzo White

Infinity Porcelain Countertop

Gallery Images

Porcelain Countertops | FAQ

Introducing Porcelain Countertop

How are the Porcelain Slabs made?

Quartzes, feldspar, clay, and kaolin are purified, atomized, pressed and heated to high temperatures in order to make up the body of the product.

With the production system, it is possible to combine various layers of colored powders in the body of the slab, perfecting the desired effect right down to the last detail.

Natura-Vein Tech | Infinity Porcelain

Natura-Vein Tech is a revolutionary innovation developed by Infinity technical staff to obtain veined slabs.

This is a GAME-CHANGING TECHNOLOGY that makes it possible to have surface veins pass through the full thickness of the porcelain slab with perfect consistency between the surface and body.

1. What are the advantages of Porcelain Countertop?

All slabs have structural, aesthetic and functional characteristics that make them an ideal choice. It is resistant to wear & tear and scratches and is not affected by heat or acid. The slabs are very easy to clean, typically requiring only mild soap and a damp cloth. Non-Absorbent. Resistant to liquid, acids, thermal shock, scratches, and abrasions. Food-safe, hygienic surface. Easy to clean

2. What is the composition of Porcelain Slabs?

They are made of 100% natural raw materials and minerals. They are the same essential elements contained in granite which, when sintered at a temperature of 1230°C, create a new, compact material with incomparable technical performance. They are the result of a combination of excellences: smart technologies, high-quality raw materials, and a deep culture in surface design.

3. How big are the slabs?

Infinity specializes in the production of large slabs, up to a maximum size of 1620mm x 3240mm (~ 63.75” x 127.5”). Sizes are available in both 12mm ( ~ 0.5”) and 20mm (~ 0.75”) thickness.

4. Can Porcelain be used beyond countertops?

The large-sized porcelain slabs can be used for furnishing accessories, for application on interior walls, or for cladding of glued or ventilated walls.

5. What are the range of Porcelain Surface finishes?

Here they are. Polished: It is obtained through a progressive mechanical grinding process. It uses micro-abrasive materials with decreasing granularity to create a perfectly reflective surface. This surface is recommended for cladding applications and for the production of various types of furnishing elements. Satin: Satin finish is the perfect synthesis between aesthetics and functionality. Perfectly smooth, soft to the touch, with a controlled and homogeneous opacity that enhances the graphic development of the slabs. A complete absence of structure maximizes cleaning capacity and daily maintenance. Matte: This finish is characterized by a light surface structure that enhances stone finishes and allows obtaining a friction coefficient suitable for floor applications. The structure of the slab remains soft and does not make the surface difficult to clean.